Skytouche adheres to the highest quality standards and undergoes the following quality tests which are frequently conducted by their quality in charge at site and we are also an ISO 9001: 2015 certified company

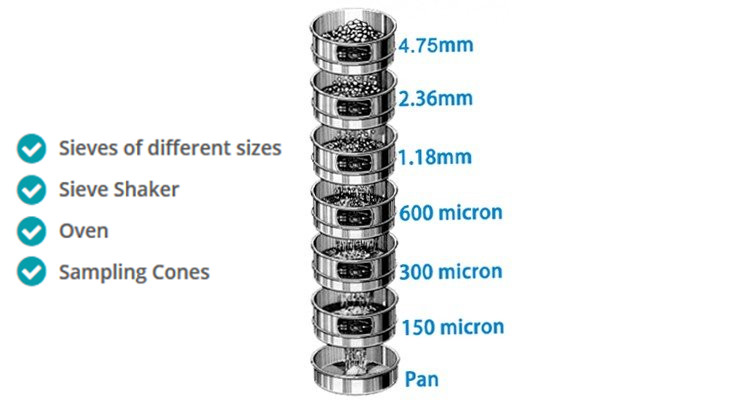

The Sieve Analysis tests are conducted on all metals everyday on samples collected from conveyor belts, stock piles and loaded trucks.

This method covers the sampling and determination of the particle size distribution of coarse aggregates. Optimum particle size distribution increases the workability of the concrete & can avoid honeycombing.

All our sales officers are also trained to carry out these tests at customer locations.

The Vertical Shaft Impactor applies a similar principle of rock-on-rock collusion for crushing.

The sand is classified into four zones as per IS 383 norms.Zone I is coarser and becomes finer towards Zone IV.

Our range of aggregates is regularly tested according to Indian Standards: IS 2430 Sampling, IS 2386 Testing, and IS 383 Aggregates for Concrete.

We continuously monitor and control the settings and parameters of the feeding, crushing and screening equipment for consistency in the finished product.

Our three-stage plant provides better control on the particle size distribution at each sieve and improved grading of GSB, coarse aggregates, and manufactured sand. Grading analysis is carried out on a daily basis.

We manage stockpiles and control the loading to eliminate contamination and segregation.

The intrinsic parameters of aggregates have an impact on the quality of concrete; hence, we take great care during the selection of the deposit.